Computational Fluid Dynamics in Industrial Combustion

Industrial Equipment. Our CFD simulation products have been validated and are highly regarded for their superior computing power and accurate results.

Using Cfd Modeling To Develop Natural Gas Burners 2020 11 16 Engineered Systems Magazine

The moving fluid creates a space devoid of downstream-flowing fluid on the downstream side of the object.

. Combustion is a process that includes two processes viz. The Finite Volume Method in Computational Fluid Dynamics. In fluid dynamics an eddy is the swirling of a fluid and the reverse current created when the fluid is in a turbulent flow regime.

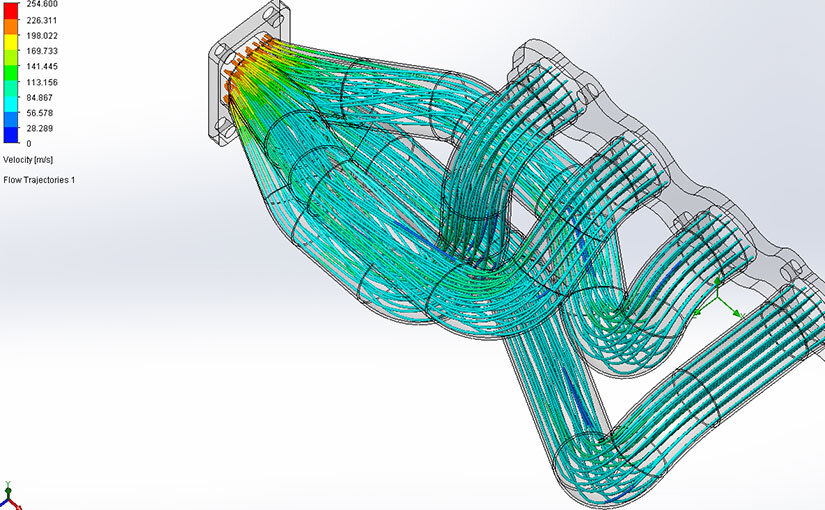

How CFD helps develop tailored burner designs for Alternative Fuels. An open source framework used in the development of a range of CFD programs for the simulation of industrial scale flow problems. POLYU ME Mechanical Engineering has been substantially shaped into todays all-round excellence in teaching research and community service thanks to the selfless devotion from generations of students academics technical and administrative staff alumni friends and.

Principles of Dynamics-Fall-Fall-AAE50800. This update includes significant advancements in GPU technology and open-source accessibility to increase productivity and reduce simulation time. Reduce development time and efforts while improving your products performance and safety.

In this study hydrogen is purified from its mixture with CO 2 using Monoethanolamine-based nanofluids in a T-junction microchannels at dynamic conditions with various lengths and diameters simulated with the aid of computational fluid dynamics. Guest blog by FCT Combustion. Ansys Fluent continues to make strides towards more efficient and sustainable computational fluid dynamics CFD simulations.

Materials Handling. Must contain at least 4 different symbols. Additive manufacturing automation technologies robotics industrial data science process simulation forming and joining hybrid products processes and machine tools AI in manufacturing intelligent materials testing.

The aim of this site is to share the extensive experience and knowledge we have gained over the years in working with Computational Fluid Dynamics. 6 to 30 characters long. This book primarily oriented towards industrial applications intends to provide engineers with the necessary background to use and understand commercial fluid dynamics modeling codes or.

From the reviews of the third edition. Where he worked on the development of a state-of-the-art turbo machinery code in OpenFOAM for heat transfer and combustion analysis. Computational fluid dynamics CFD is a science that with the help of digital computers produces quantitative predictions of fluid-flow phenomena based on the conservation laws conservation of mass momentum and energy governing fluid motion.

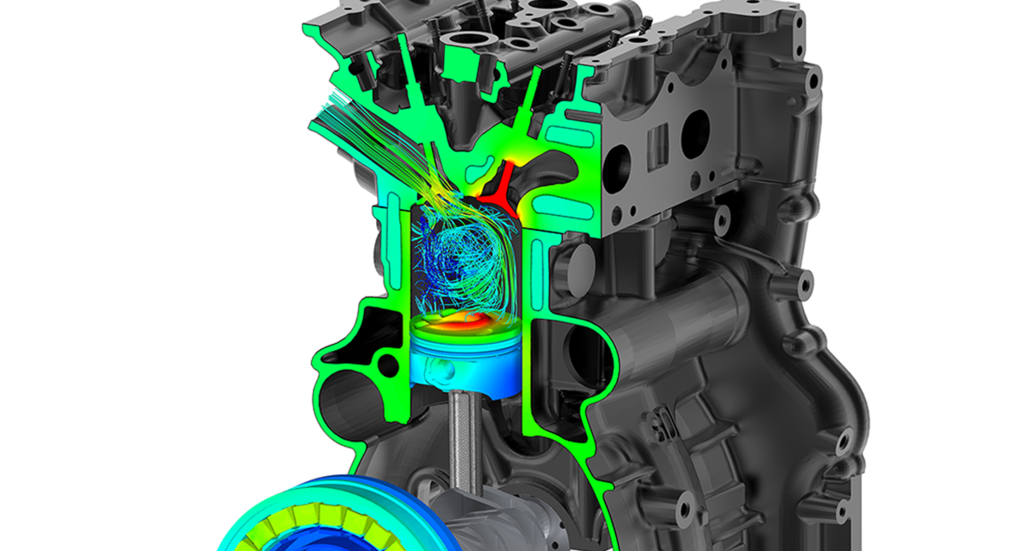

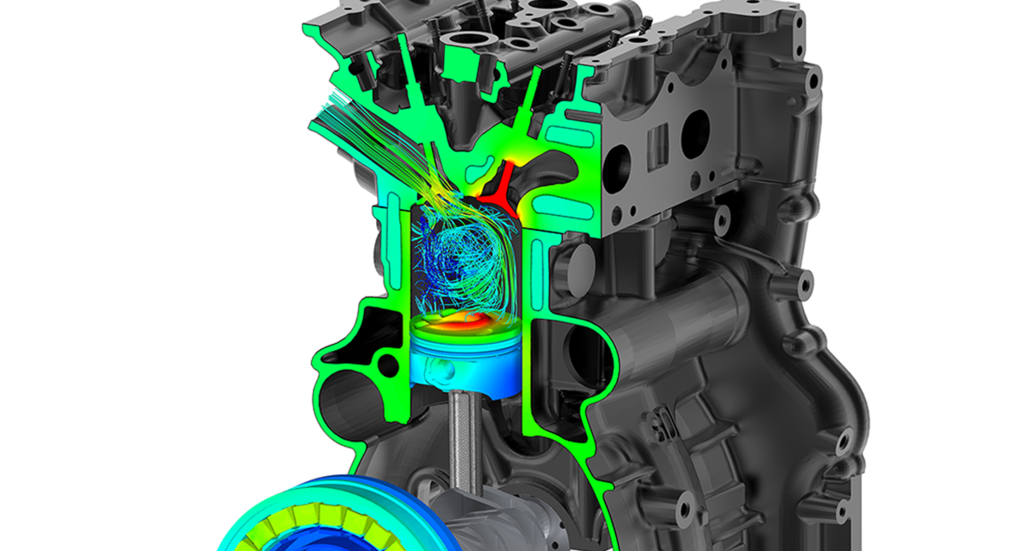

Discrete Element Method DEM. Computational Fluid Dynamics CFD Fatigue Analysis. 2015 internal combustion engine Tian and Abraham 2014.

In most industrial applications forced convection is used for effective and efficient heat transfer in applications like steam turbines heat exchangers etc. Introduction to Fluid Mechanics. Trucks Trailers.

14 The Impact of Computational Fluid Dynamics-Some Other Examples 13 14. L Automobile and Engine Applications 14 142 Industrial Manufacturing Applications 17 143 Civil Engineering Applications 19 144 Environmental Engineering Applications 20 l45 Naval Architecture Applications Submarine Example 22 15 Computational Fluid Dynamics. Navier-Stokes and continuity equations reaction rate and two-phase transport models are utilized in.

Ansys computational fluid dynamics CFD products are for engineers who need to make better faster decisions. Optimization in Aerospace Engineering. ASCII characters only characters found on a standard US keyboard.

Thermal and chemical in which a hydrocarbon fuel reacts with an oxidant to form products accompanied by the release of. Fluid behind the obstacle flows into the void creating a swirl of fluid on each edge of the obstacle followed by a short reverse flow of fluid. Converging combustion problems can be very difficult at times due to the high coupling between the flowturbulence energy due to reaction heat release radiation particle tracking etc.

The aim of this site is to share the extensive experience and knowledge we have gained over the years in working with Computational Fluid Dynamics. High-speed radiography computational fluid-dynamics multi-physics simulations. LEAP Australia is the leading engineering software solutions provider in Australia and New Zealand assisting thousands of companies with their design and engineering problems.

Combustion Process Cfd Analysis

Avl Fire Avl Fire Avl Fire Avl Com

Applications Of Cfd In Automotive Industries

Computational Fluid Dynamics In Hvac Design Simscale

0 Response to "Computational Fluid Dynamics in Industrial Combustion"

Post a Comment